Hefei Hengcheng Industrial Equipment Technology Co., Ltd.

(hereinafter referred to as Hengcheng) was established in 2008. The

company is located in Hefei, Anhui, a famous science and education

city in China. It is a national-level high-tech enterprise and

technology-based enterprise specializing in powder industry

technology and equipment R&D, manufacturing, sales and service.

The company has passed the ISO9001 international quality system

certification.

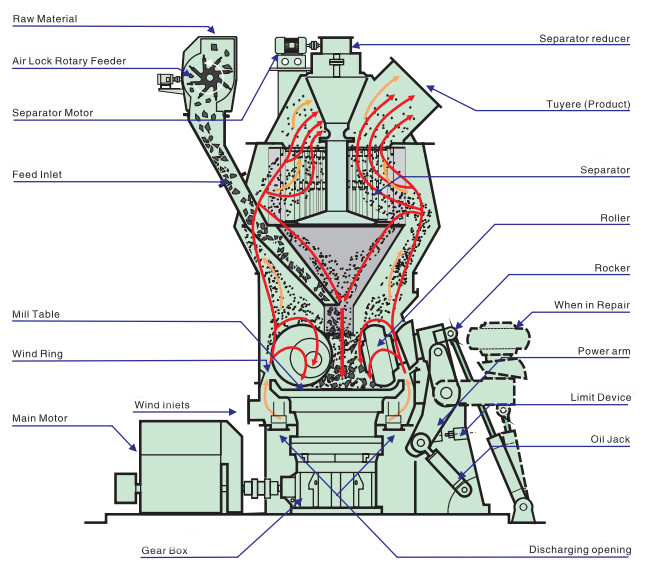

Our company's main products : Vertical Coal Mill,Limestone Vertical

Mill,Vertical Raw Mill,Slag Grinding Mill,Gypsum Grinding

Mill,Calcite Mill,VRM Cement Mill,Bentonite Grinding Mill,Dolomite

Grinding Mill,Bauxite Grinding Mill and pneumatic conveying system

equipment. Among them, the grinding system equipment includes HVM

vertical mill, rotary air lock feeder, and pressure-resistant

sealed metering feeder. The products of the pneumatic conveying

system equipment include PCD type positive pressure dense phase

pneumatic conveying bin-type pump, PJP type positive pressure

dilute phase pneumatic conveying jet pump, and HL type

high-efficiency pneumatic fluidized blanking and blockage removal

device.

Since its establishment, the company has always adhered to the

development concept of "Based on Industry and Equipped in the

World", and is committed to providing domestic and foreign

customers with a complete set of system solutions in the powder

industry field covering powder industry preparation, engineering

design, engineering general contracting and technical services and

consulting. Program. The company's core technology products have

been widely used in the powder processing fields of building

materials, metallurgy, chemical industry, heat, energy, electric

power, lime kiln, pellets, mineral processing (including metal and

non-metallic minerals), port warehousing and logistics and other

industries.

The company has a professional technical team composed of

high-quality talents such as experts and scholars, senior engineers

and postgraduates who have won the National Science and Technology

Progress Award and participated in the formulation of relevant

industry standards. Practical experience, has rich engineering

practice experience and theoretical basis. At the same time, the

company has established technical cooperation and exchange

relations with a number of key universities, absorbed the

cutting-edge technologies in the powder industry at home and

abroad, and closely followed the development trend of the powder

industry, so as to provide customers with advanced and reliable

powder equipment and various professional services. Technical

Services.

Aiming at the two important links of powder preparation and powder

transportation in the powder industry, the company has deeply

studied the physical and chemical properties of various types of

powder materials in different industries and fields after years of

technical accumulation and a large number of engineering practices.

On this basis, we have developed powder processing technology and

complete sets of equipment that are highly targeted, safe,

reliable, efficient and energy-saving.

We have a professional technical team composed of experts and

scholars, senior engineers and postgraduates who have won the

National Science and Technology Progress Award and participated in

the formulation of relevant industry standards. All team members

have more than ten years of experience in large state-owned design

institutes in the industry Experience, has a wealth of engineering

practice experience and theoretical basis. It can provide

professional and systematic engineering design services for

customers in various industries involving grinding system and

pneumatic conveying system engineering, and provide a complete set

of solutions in the field of powder engineering.

We have undertaken a large number of domestic and foreign

(currently the company exported to Indonesia, Vietnam, the

Philippines, Pakistan, Egypt, Yemen, Saudi Arabia, Congo and other

countries and regions in the world) the metallurgical industry

limestone powder milling and pneumatic powder conveying projects

and coal powder preparation And pneumatic conveying project, lime

kiln industry pulverizing and pneumatic powder conveying project,

coal powder preparation and pneumatic conveying project, cement

industry grinding system and conveying system renovation project

and other engineering design projects, the design of the

engineering project equipment selection is reasonable, The design

scheme is scientific and reasonable, concise, practical, and

cost-effective, all of which have reached or exceeded the expected

indicators, and have been highly recognized and praised by users.

The project has won the company's reputation in the industry.

Our goal: to sell the best machines at the best prices with

industry-leading customer service. We personally know each of our

customers, always adhering to the development concept of "Focus On Powder,Equipping The World", we are committed to providing powder industry services covering

powder industry preparation, engineering design, engineering

general contracting and technical services and consulting for

customers around the world. A complete set of system solutions in

the field.

For more detailed information on our Powder Industry Technology and

Equipment, please do not hesitate to contact us! We welcome your

inquiries, and look forward to working with you.